Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you buy today?

- Thread starter WoodiE

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

Diem Turner

Yes...I have a Premium Member

Premium Member

Rig of the Month Winner

Build Thread Contributor

Top notch man. I do love me some Knipex pliers/side cutters/flush cutters/just about anything they make. They work exceptionally well, they're comfortable and ergonomic to use and they're super robust. You keep them forever, just like luggage and herpes.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,760

- Reaction score

- 42,250

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

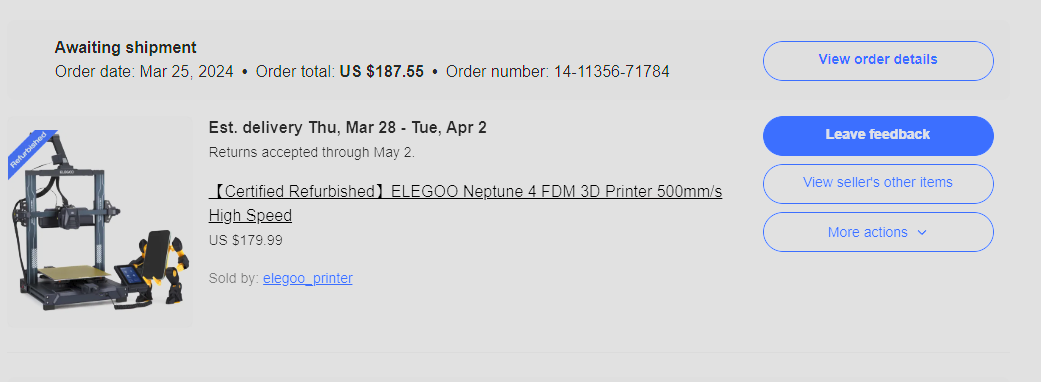

So I uh did a thing.

Plexiglass will work but not for long even on a 1/10th scale it cracks really easily.Bought a piece of plexiglass to try and fabricate an ESC mount out of. Also bought another Ram body for my Kraton b/c I absolutely hate the way the first one came out using Traxxas paints.

View attachment 356859

Diem Turner

Yes...I have a Premium Member

Premium Member

Rig of the Month Winner

Build Thread Contributor

Nice man. Yeah, a 3D printer is def still on my "do-want" list.So I uh did a thing.

View attachment 356939

Plexiglass will work but not for long even on a 1/10th scale it cracks really easily.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,760

- Reaction score

- 42,250

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

Now I'm off to spend more on filament than I did the printerNice man. Yeah, a 3D printer is def still on my "do-want" list.

Diem Turner

Yes...I have a Premium Member

Premium Member

Rig of the Month Winner

Build Thread Contributor

lol, yeah. To be fair though, it's amazing for what prices you can get 3D printers these days. They've come a long way in a relatively short amount of time if you think back to when they first hit the market.Now I'm off to spend more on filament than I did the printer

- Messages

- 1,680

- Reaction score

- 4,627

- Location

- Florida

- Arrma RC's

- BigRock 4x4

- Fireteam

- Infraction

- Kraton 8S

- Kraton 6s

- Mojave

- Senton 3s

- Typhon 3s

Plexiglass will work but not for long even on a 1/10th scale it cracks really easily.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,760

- Reaction score

- 42,250

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

Yeah. I tried some 3mm Lexan that held up a lot longer but it also eventually cracked.

Diem Turner

Yes...I have a Premium Member

Premium Member

Rig of the Month Winner

Build Thread Contributor

You should sandwich it between two thin CF sheets with epoxy (I'm even thinking that something really thin like 0.2mm CF sheet would do the job and that wouldn't even cost you much at all). That should add just enough strength to keep the acrylic in one piece (or however many pieces it was intended to be made of). Just some food for thought.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,760

- Reaction score

- 42,250

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

Carbon fiber works well for esc mounting plates. I have had the Basherqueen cf esc mount in my Kraton 6s EXB for a couple of years now without issues.You should sandwich it between two thin CF sheets with epoxy (I'm even thinking that something really thin like 0.2mm CF sheet would do the job and that wouldn't even cost you much at all). That should add just enough strength to keep the acrylic in one piece (or however many pieces it was intended to be made of). Just some food for thought.

- Messages

- 6,174

- Reaction score

- 9,035

- Location

- Illinois

- Arrma RC's

- Fireteam

- Infraction

- Limitless

- Kraton EXB

- Talion

- Typhon 6s

- Typhon TLR

You have a 3D printer now - you’ll never buy another ESC plate.Carbon fiber works well for esc mounting plates. I have had the Basherqueen cf esc mount in my Kraton 6s EXB for a couple of years now without issues.

slick2500

Anything will break if you drive it wrong enough.

Community Leader

Premium Member

ArrmaForum Fan

Excellence Award

Build Thread Contributor

- Messages

- 26,760

- Reaction score

- 42,250

- Location

- Rapid City, SD

- Arrma RC's

- Fireteam

- Kraton 6s

- Kraton EXB

- Outcast 6s

- Senton 3s

- Typhon 3s

But @305HemiGuy doesn't. Just trying to help a brotha out.You have a 3D printer now - you’ll never buy another ESC plate.

Diem Turner

Yes...I have a Premium Member

Premium Member

Rig of the Month Winner

Build Thread Contributor

Yeah, CF is perfect for applications like that (and many more obviously). I started doing my own CF layups about two months ago and I'm well pleased with the results. I'm just using stuff most people probably have somewhere in the house and the final product is really, really strong. Now, is it going to compete with professional grade Toray 3K carbon fiber that you get from people like David at Scorched? Of course not. I don't have the kind of press you'd need to that kind of density but , these are some sheets I made using one of those kitchen vacuum devices for making sous vide or putting stuff in the freezer, two plexiglass plates to sandwich the CF between and a 50lb. block of plaster.Carbon fiber works well for esc mounting plates. I have had the Basherqueen cf esc mount in my Kraton 6s EXB for a couple of years now without issues.

This is a single layer of 400g/m² carbon cloth. That'll give you a flexible sheet of CF @0.38mm. I think if you were to epoxy this to both sides of an acrylic sheet, that should make it quite durable.

And this piece is 8-ply 400g/m² carbon cloth which yields a bone hard 3mm plate.

@305HemiGuy, if you want to skip the plexiglass ESC mount, I can send you this 3mm plate. Overall dimensions are approx. 190x130mm, that should be more than enough for the purpose. No money. If you're interested, shoot me a PM. I'll just need your name and address and whether you'd prefer a matte finish or high gloss as it still needs one last shot of lacquer. Lemme know.

Greengaunja

Ise da by' dat burns da Senton........

Premium Member

ArrmaForum Fan

Build Thread Contributor

- Messages

- 2,662

- Reaction score

- 4,521

- Location

- Durham Region, Ontario Canuckistan

- Arrma RC's

- Senton 6s

- Senton 3s

You are right about gaining strength by just adding a thin layer of CF sheet. It's how I did my "splitter areodynamic thingy" so the Senton could keep the Limitless front end and maybe, just maybe improve the air flow of the brick wall the Senton has up front.Yeah, CF is perfect for applications like that (and many more obviously). I started doing my own CF layups about two months ago and I'm well pleased with the results. I'm just using stuff most people probably have somewhere in the house and the final product is really, really strong. Now, is it going to compete with professional grade Toray 3K carbon fiber that you get from people like David at Scorched? Of course not. I don't have the kind of press you'd need to that kind of density but , these are some sheets I made using one of those kitchen vacuum devices for making sous vide or putting stuff in the freezer, two plexiglass plates to sandwich the CF between and a 50lb. block of plaster.

This is a single layer of 400g/m² carbon cloth. That'll give you a flexible sheet of CF @0.38mm. I think if you were to epoxy this to both sides of an acrylic sheet, that should make it quite durable.

View attachment 356949View attachment 356950

And this piece is 8-ply 400g/m² carbon cloth which yields a bone hard 3mm plate.

View attachment 356951View attachment 356952

@305HemiGuy, if you want to skip the plexiglass ESC mount, I can send you this 3mm plate. Overall dimensions are approx. 190x130mm, that should be more than enough for the purpose. No money. If you're interested, shoot me a PM. I'll just need your name and address and whether you'd prefer a matte finish or high gloss as it still needs one last shot of lacquer. Lemme know.

Here's some perspective: this was formed with cardboard and insulative foam.

Among the lessons I learned with CF is to always leave the clear coat until you are done all cuts and have drilled all holes. Because it will scratch up, even if you tape it off. Running water and the finest wet paper you can get give the best results.whether you'd prefer a matte finish or high gloss as it still needs one last shot of lacquer.

Warby

"Hurry up and wait"

Premium Member

ArrmaForum Fan

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 4,780

- Reaction score

- 12,950

- Location

- Australia, WA.

- Arrma RC's

- ADX-10

- BigRock 4x4

- Limitless

- Kraton 6s

- Senton 3s

- Senton Mega

- Typhon 3s

- Typhon 6s

- Infraction 4x4

Yes I have quite the collection of Knipex these days. At Home and work. I don't mind spending money on them knowing their quality. Especially when they are on sale.Top notch man. I do love me some Knipex pliers/side cutters/flush cutters/just about anything they make. They work exceptionally well, they're comfortable and ergonomic to use and they're super robust. You keep them forever, just like luggage and herpes.

I've never broken one. Worn them out from lots of use, yes. The Knipex pliers and cutters are better than Snap-on or any other brand I've used.

speeding_Infraction

Very Active Member

I will ask him what he was using. If you're gonna go on dry rocks get something nice and sticky. What he was running was more for dirt and mud.The rear wheels rub on the frame or arms of the rear axle just a bit if you steer to hard- that's my only beef with it, but other than that, solid crawler. Do you have a recommendation for what kind of tires to run? Part numbers are helpful.

AMAIN is having a crawler sale. https://www.amainhobbies.com/fms-fc...cro-rock-crawler-black-fmm11851rtrbk/p1548454

My favorite time of year... upgrade time!

That'll set ya back,eh? Nice. FWIW, that's more than I paid for a used 1:1 car!!