JRG4ARRMA

Member

- Messages

- 28

- Reaction score

- 73

- Arrma RC's

- Kraton 4s

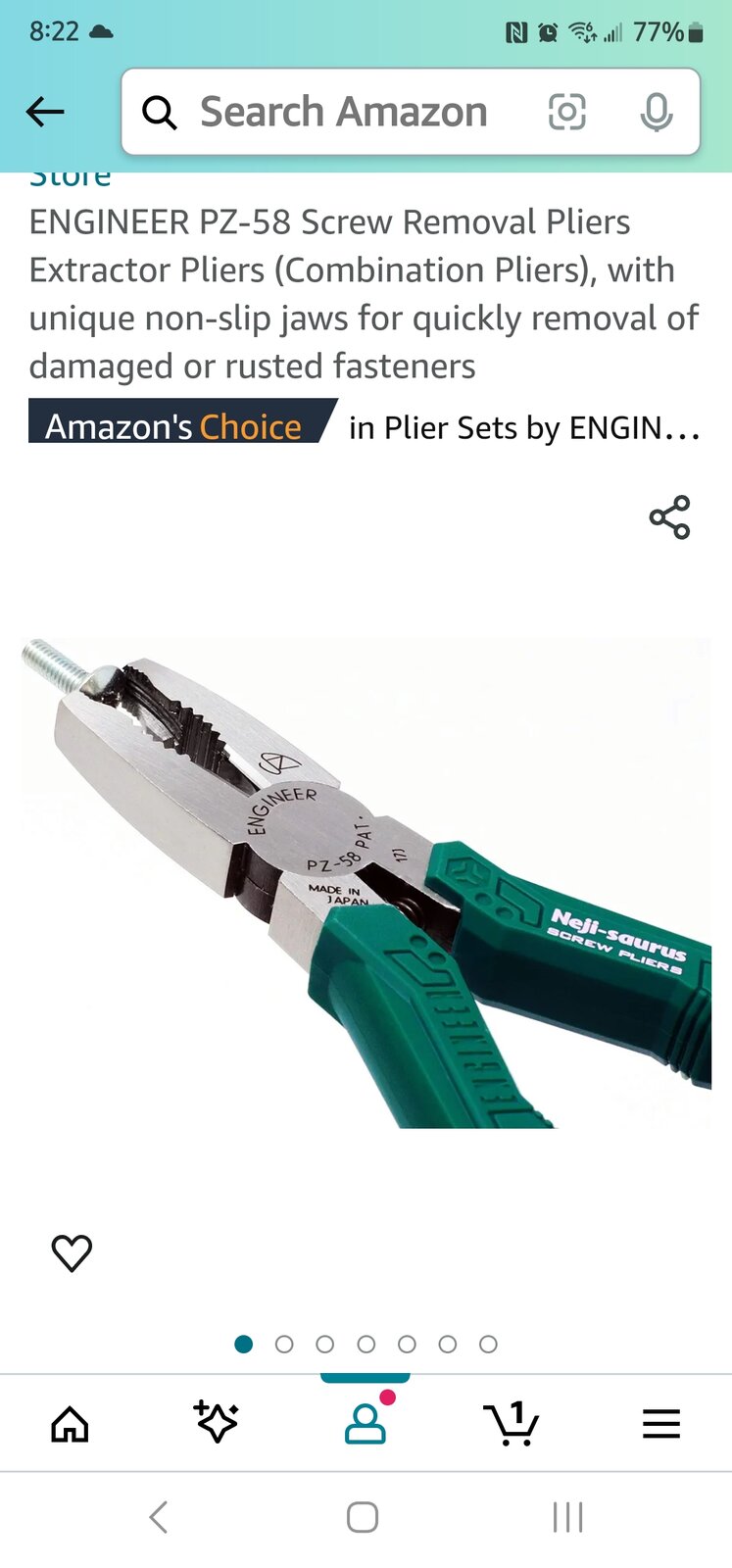

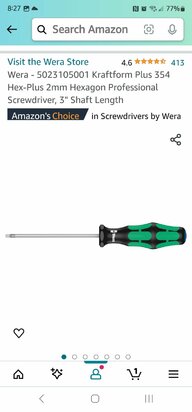

So I’m checking the center diff fluid before running my new rig and I stripped a screw head trying several methods to remove it. I think it’s probably got too much loctite from the factory. Any suggestions for removing it? The other three are loose and I had no trouble with the rear diff.