Mopsik_Klopsik

Active Member

How tight do I need to screw down this nut? Does the nut has to be screwed fully on or should I back off the nut so that the piston has a little bit of movement?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I agree. Emulsion systems are a foolproof way to cause foaming in the shock oil and epic shock fade. You’re also basically killing the rebound of these shocks. I’ve never understood the draw.Try it both ways, you'll feel the difference in function.

I wouldn't take anything seriously from a guy promoting emulsion caps and installing a boot on his shaft.

Once the boots tear I leave the bottom rubber ring for full compression absorption so the arm can flex a bit and no CVD disengagement. Otherwise I'll rebuild with a few mm of compression tube sleeved.Not that I haven’t historically installed boots on my shaft periodically…

When I was talking about installing boots on my shaft I wasn’t talking about RC shocks…Once the boots tear I leave the bottom rubber ring for full compression absorption so the arm can flex a bit and no CVD disengagement. Otherwise I'll rebuild with a few mm of compression tube sleeved.

When I was talking about installing boots on my shaft I wasn’t talking about RC shocks…

For many people, the common approach seems to be “tighten the living heck out of it.” In most cases this is poor advice.Most kits will say the same thing….

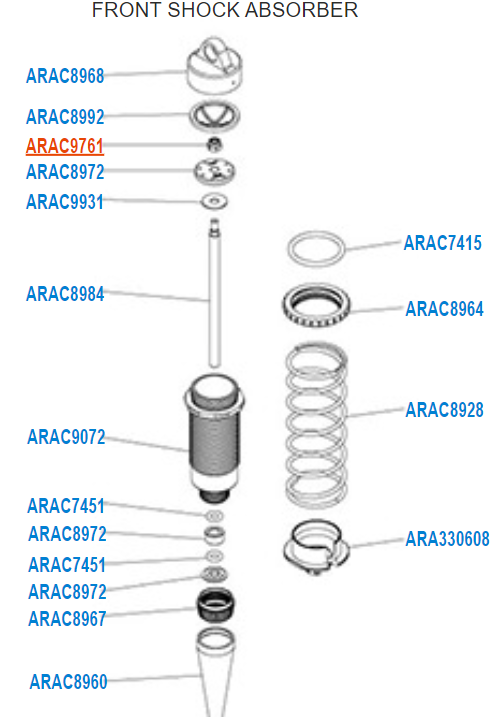

View attachment 351206

Register and gain access to Discussions, Reviews, Tech Tips, How to Articles, and much more - on the largest Arrma RC community for RC enthusiasts that covers all aspects of the Arrma-RC brand!

Register Today It's free! This box will disappear once registered!