- Messages

- 4,368

- Reaction score

- 13,354

- Location

- North Liberty, IA

- Arrma RC's

- Infraction

- Kraton 6s

- Typhon 3s

- Typhon 6s

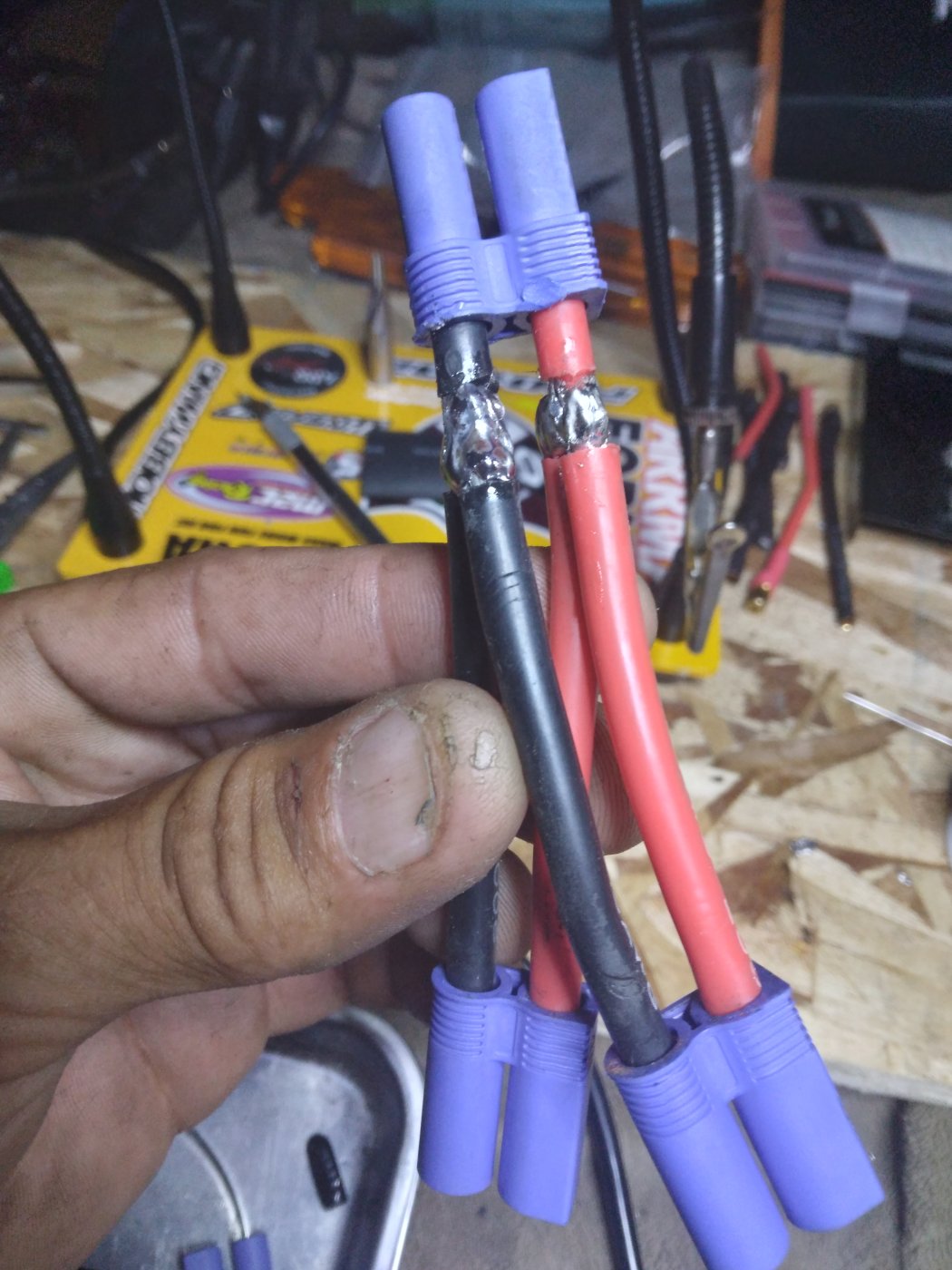

Good evening arrma fam! Need a parallel wiring harness for some batteries & didn't want to wait for the ones I bought so I thought I'd try to make one out of stuff that I have on hand. Really testing my skill level here & I couldn't really find pics or videos that really helped. I just need to know if this is safe to use or am I risking a call to the fire department. Bear in mind that I will of course wrap both pos & neg separately before heat shrinking them together. Please be kind (but honest!), this is my 1st attempt @ anything like this