- Messages

- 3,079

- Reaction score

- 5,969

- Location

- Mechanicsville, MD

- Arrma RC's

- Infraction

- Kraton 6s

- Typhon 3s

- Infraction 4x4

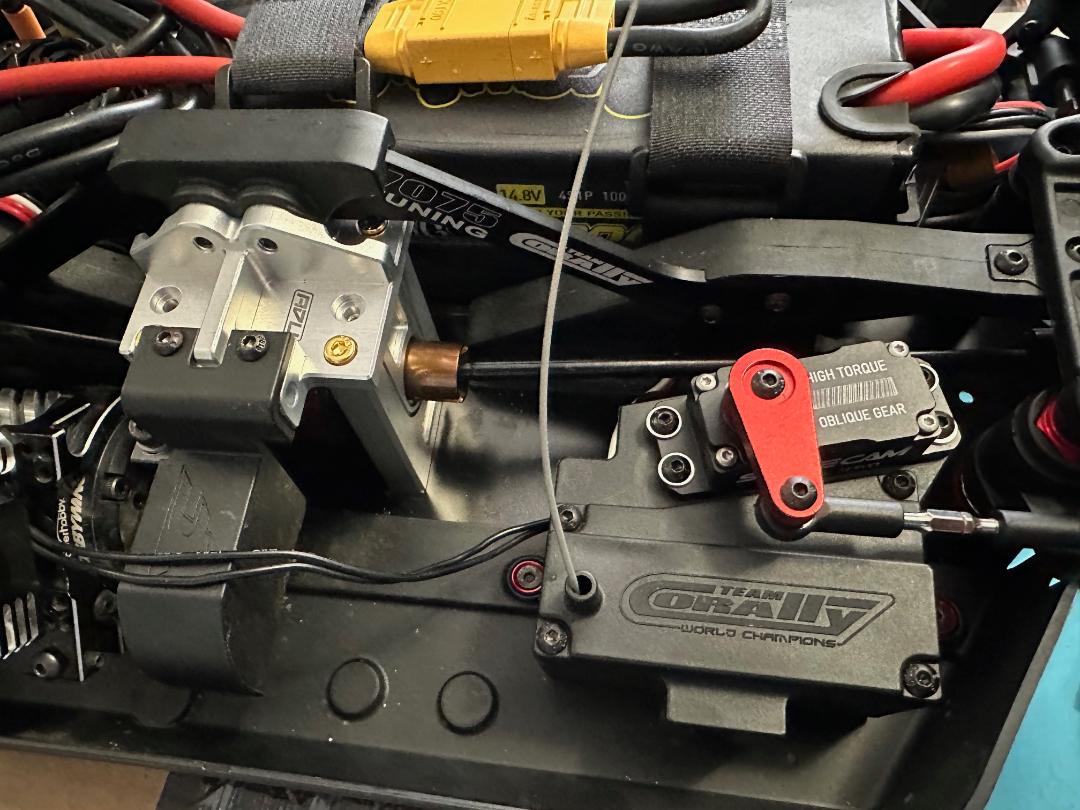

I upgraded the center diff support on my Asuga to ADU Racing 7075 parts and replaced the top center brace with a TC 7075 brace. Since the diff was accessible, I checked and filled the diff fluid to the proper level - it was half full, as I expected.

I had not checked the center diff fluid previously due to the effort involved: taking out the center diff on an Asuga is a PITA. The center brace has to be removed because it goes over the center diff cover, and to do that you have to remove the motor and servo mount/receiver box to get to the top brace screws. Not all that hard, it's just time consuming. Installing the ADU parts was the perfect time to do diff maintenance: I won't be touching the center diff again for a long while.

Edit: Since this pic was taken, I installed four stock black screws to fill in the holes in the diff top late. ADU only included enough screws to cover the center diff support and four of the support insert screws: the screws for the motor mount come with the ADU motor mount and are not included with the center diff parts.

I had not checked the center diff fluid previously due to the effort involved: taking out the center diff on an Asuga is a PITA. The center brace has to be removed because it goes over the center diff cover, and to do that you have to remove the motor and servo mount/receiver box to get to the top brace screws. Not all that hard, it's just time consuming. Installing the ADU parts was the perfect time to do diff maintenance: I won't be touching the center diff again for a long while.

Edit: Since this pic was taken, I installed four stock black screws to fill in the holes in the diff top late. ADU only included enough screws to cover the center diff support and four of the support insert screws: the screws for the motor mount come with the ADU motor mount and are not included with the center diff parts.

Last edited: