norcopunk

Active Member

- Messages

- 101

- Reaction score

- 41

- Arrma RC's

- Raider

- Senton 6s

- Vorteks

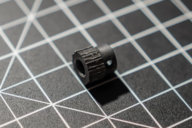

I hear a lot of stories about people busting pinions and/or shredding spur gears on the 1/8 line up due to pinion failure.. Should I be upgrading pinions immediately on a brand new truck to prevent more damage later on?