firehawk_77

Active Member

Hey everyone,

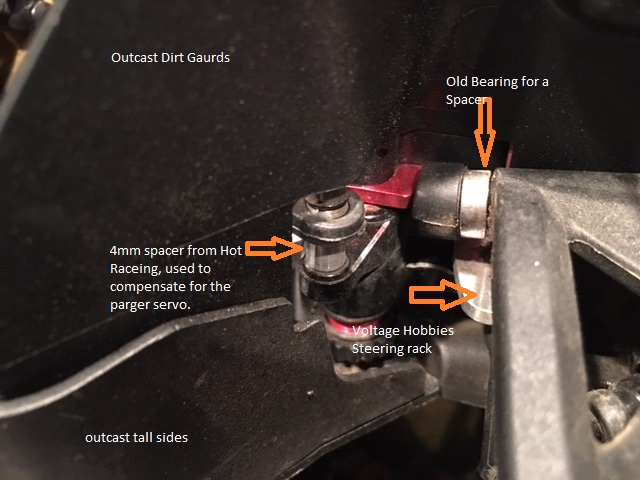

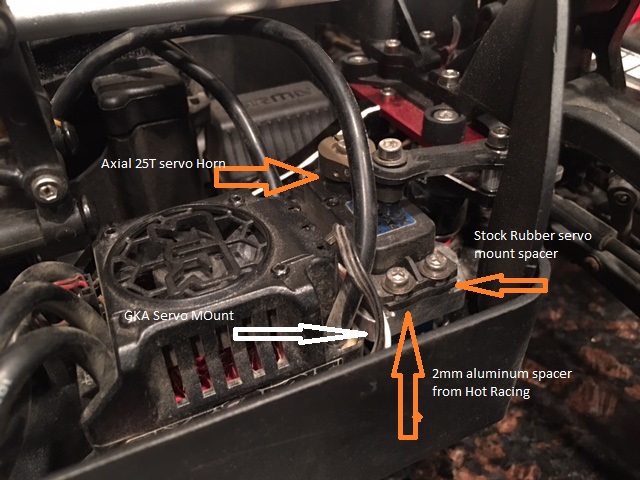

I am new to the Outcast, but not RC's in general. After my first bash I managed to break the right front lower a arm. Several days later and I've replaced the front with RPM upper and lowers on the front and put a Voltage servo mount in. I just finished buttoning everything up and turned on the TX and RX. Nothing seemed amiss but when I tried to turn the servo saver moved up not the tires. I tried to see if anything I installed could cause the binding but I'm at a loss. With the power off it's difficult to move the tires but it can be done, but not under power. I'm at the point of taking it apart all the way, but hoping someone on here has experienced something like this and could point me to something I'm missing.

I am new to the Outcast, but not RC's in general. After my first bash I managed to break the right front lower a arm. Several days later and I've replaced the front with RPM upper and lowers on the front and put a Voltage servo mount in. I just finished buttoning everything up and turned on the TX and RX. Nothing seemed amiss but when I tried to turn the servo saver moved up not the tires. I tried to see if anything I installed could cause the binding but I'm at a loss. With the power off it's difficult to move the tires but it can be done, but not under power. I'm at the point of taking it apart all the way, but hoping someone on here has experienced something like this and could point me to something I'm missing.